SHAREBOT SNOW WHITE

Direct Laser Sintering (DLS) Professional 3D Printer that uses laser sintering technology aiming the laser automatically at points in space, binding the material together to create a High Resistance solid structure.

Compared to other 3D printing technologies, the main advantages of laser sintering are:

- The ability to build objects of any shape without using supports;

- The thermal and mechanical resistance of the objects that can be made;

- The possibility of reusing the non-sintered material.

Having a CO₂ laser, the printer allows the user to experiment with a wide range of professional thermoplastic powders, including PA 12, PA 11, and TPU, each one with different technical properties. Special loaded powders can also be used, that is, containing particles of other materials such as glass, carbon or aluminum, which give the resulting objects different mechanical, physical or visual properties.

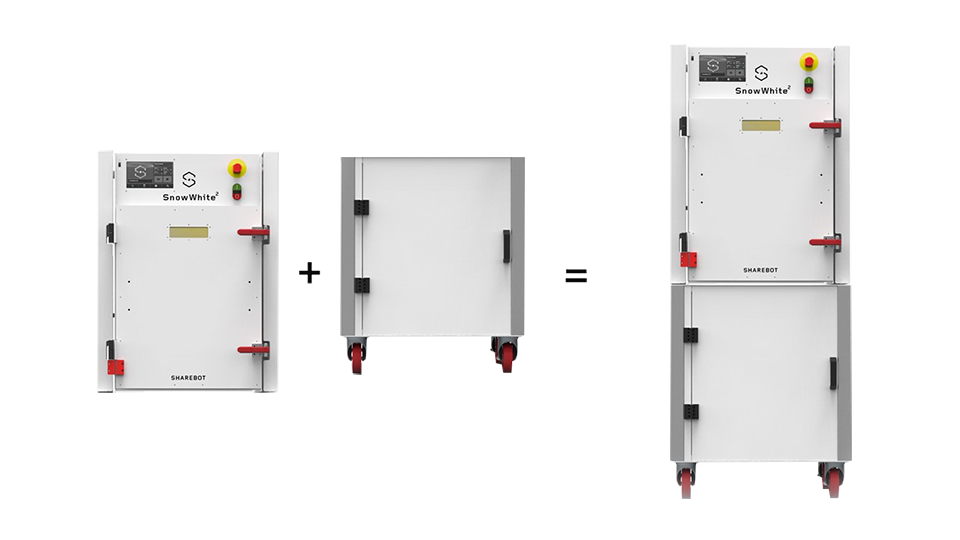

SnowWhite 2 also has the possibility of being integrated with a module that allows controlling the atmosphere inside the printing chamber thanks to the oxygen presence sensors that regulate the flow of the inert gas chosen to alter the printing atmosphere.

SnowWhite was created to bring the advantages of sintering to small and medium-sized companies and laboratories, all in an economic, simple and effective way without sacrificing the professional quality of the result. The user can really “print in one click” because, once the profile of the material has been defined, the printing process is completely autonomous, requires no external intervention and the results are perfectly repeatable.

Compared to other printers that use the same technology, start-up time takes less than 10 minutes, in fact, you can switch from loading the material to the production of the first layers in 10 minutes. The average electrical consumption is less than 1.5KWatt / hour and all unused powder is recycled and can be directly reused in subsequent processing.

You can start printing using only 300 grams of material.