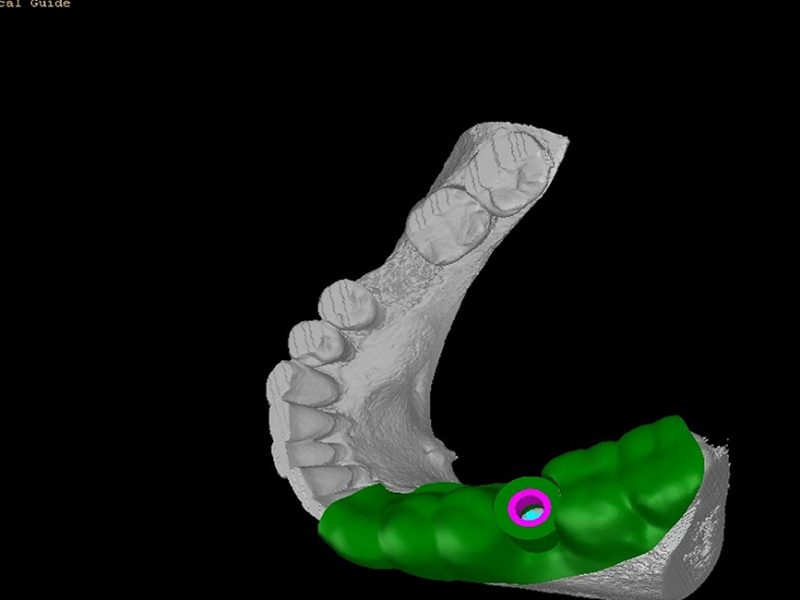

SURGICAL IMPLANT GUIDE and MANUFACTURING

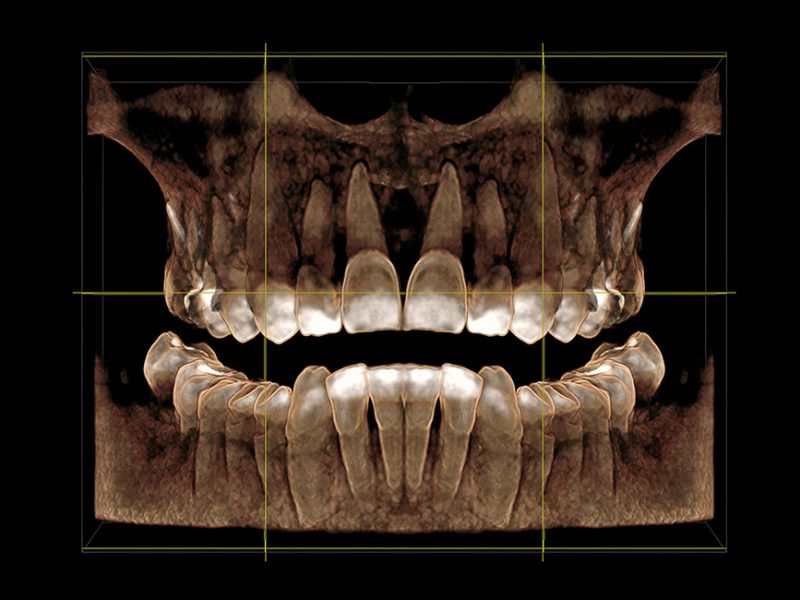

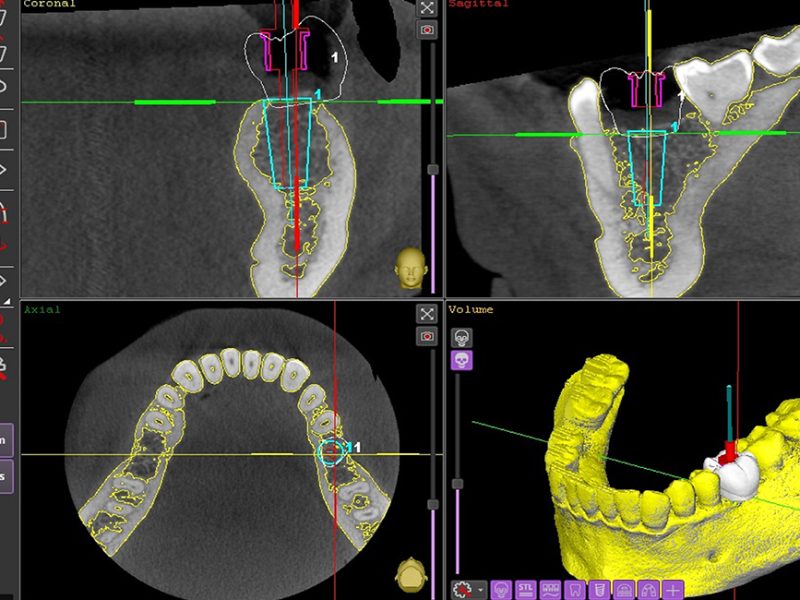

In dental surgery, we design and manufacture the dental part known as “guide” or “surgical guide or template”. The task of the guide ensures that the physician positions the implant at the right angle on the bone.