SHAREBOT METALONE

METAL 3D PRINTER

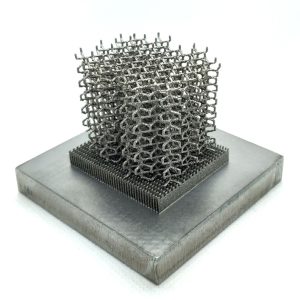

Sharebot MetalONE is a metal sintering 3D printer aimed at research and production of small and medium-sized metal parts. The peculiarity is in the so-called “shell printing” (patent pending) that allows ease of use, speed, and better control of the printing chamber.

APPLICATIONS

The ideal metal 3D printer for all those who want to test new materials and thanks to its printing area and the standard DMLS printing process, it allows the creation of objects and specimens with little use of metal powder (only 800gr), besides the fact that all the process parameters can be modified by the researcher and checked in the logs after printing. Thanks to the possibility of use with both Nitrogen and Argon and its 250 watt fiber laser, almost any dust can be tested.

The possibility of using cobalt chrome powders combined with the speed and ease of use allows the dental laboratories to make restorations, crowns or a plate of copings in less than 1 hour

Small parts with incredible details can be easily prototyped and produced in a short time and without any particular difficulty. The extreme repeatability of the prints can guarantee the production of a series of pieces. Furthermore, the pieces produced are through a high-quality standard process

MetalONE thanks to its reduced working chamber and the particular structure of the paper filters, it is also useful for the sector of additive jewelry and micro-objects. Its 250 Watt laser combined with a 10 micron layer and a 40 micron spot makes it possible to create particularly detailed objects in a short time

Today the profiles for 316L steel and cobalt chrome are available. At the time of delivery we will also have available Titanium and Aluminum. Our R&D team and some universities are testing special powders and alloys that will be released and documented in the metalONE CLUB area.